When U.S. Environmental Protection Agency regulations for snowmobiles started in 2006, Ski-Doo already had its 600 H.O. SDI two-stroke engine on the snow for two years. It was considerably cleaner than regulations required and it achieved industry-leading fuel economy. The engine was light, powerful, dependable and clean.

As the Bombardier Recreational Products (BRP) Evinrude group developed the E-TEC system for its outboard motors (BRP acquired Evinrude in 2001), it became clear that this technology could translate directly to Ski-Doo snowmobiles. In the winter of 2008, Ski-Doo released the 600 H.O. E-TEC engine.

Is the E-TEC engine a big deal in the world of snowmobiling? Absolutely. It demonstrates that the two-stroke engine — with all of the advantages it offers for snowmobiling — is far from being axed from snowmobile manufacturers’ product plans. The 600 H.O. E-TEC is available across Ski-Doo’s 2009 lineup and further expansion of the direct injected technologies will prove the strength of the two-stroke engine design and its attributes.

2 Stroke Future

The U.S. Environmental Protection Agency (EPA) imposed emission restrictions on snowmobiles in 2006, which put limits on the levels of carbon monoxide (CO) and hydrocarbons (HC) that could be present in the exhaust. There was no imposition of what type of engine manufacturers could use. If a two-stroke engine could run clean enough to meet the regulations, it would be accepted.

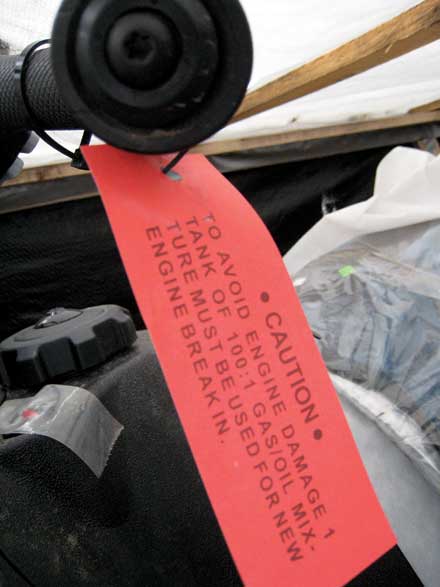

When emission regulations were applied to on-road motorcycles in the mid-1970s, all manufacturers switched to four-stroke engines for their bikes. Almost 40 years later, the 600 H.O. E-TEC has considerably lower CO emissions than any four-stroke snowmobile engine in production. The E-TEC engine brings a whole host of innovations, including an easier cold-start; electronic oil injection; a fuel-cooled engine management computer and a push-button summerization procedure.

The outboard motor industry went under regulation in 1998. Most manufacturers quickly converted to four-stroke engine designs, but they received backlash almost as fast because engines were heavier and more expensive.

Now, virtually every outboard manufacturer offers both two- and four-stroke engines. The one manufacturer that stayed exclusively with two-stroke engines for its outboards is BRP and its Evinrude brand. The E-TEC direct injection system was developed to meet the emission standards while providing less weight and good performance and fuel economy at a lower cost than competing four-stroke engines.

Other Direct Injection Systems

In the early 1990s, an Australian firm, the Orbital Engine Company, developed a two-stroke automobile engine that met then-current U.S. emissions requirements, exceeded the four-stroke fuel efficiency numbers, weighed almost 200 pounds less than a four-stroke that produced similar power, vibrated less than an equivalent four-stroke and cost from $300 to $500 less to manufacture.

Needless to say, the transportation industries got excited with Orbital’s demonstration. Ford Motor Company, General Motors, Mercury Marine, Outboard Marine Corporation, Polaris Industries, Bombardier — and likely many other engine manufacturers — soon bought patent licenses to use Orbital’s concepts for clean two-stroke development programs.

Automobile companies around the world have launched direct-injection projects, many of which don’t include Orbital’s design. The variety of concepts being developed is impressive and each one seems to confirm the ability to overcome the perceived two-stroke bug-a-boos of suffering from poor economy and high emissions.

Mercury Marine uses Orbital technology in its two-stage, direct-injection two-stroke outboards. The Dodge Neon car was originally slated to have a direct-injected, two-stroke engine, but development of the engine was delayed and a small four-stroke went to production.

Polaris has license to the Orbital patents and has been working on two-stroke engines that are cleaner than its current Cleanfire semi-direct injection systems. Arctic Cat is committed to two-stroke engine designs for its snowmobiles and it is working on direct injection designs.

Yamaha builds two-stroke outboards with High-Pressure Direct Injection (HPDI). The 200 HPDI engine has twin, high-speed fuel pumps that pressurize the gas up to 1,000 psi, and then inject the fuel after the exhaust ports are closed. The system is similar to injection systems on diesel engines.

The 2-Stroke Of Tomorrow Is Evolving

Research continues by companies that have purchased license to use Orbital’s technology and GM, Ford and others have developed two-stroke designs of their own. Most of these engine designs utilize crankcase scavenging (crankcase pressure is used to push exhaust gasses out of the combustion chamber) and total-loss lubrication systems (oil essentially becomes part of the fuel charge). All designs scavenge the cylinders only with air, incorporate some means of varying the exhaust timing, include a multiple-chamber cylinder head and utilize air-assisted fuel injection.

French automaker Peugeot and its concept two-stroke engine incorporates a poppet valve that seals a pre-combustion chamber until fuel is delivered. Rather than use a separate air pump to supply the air-assist for injection, Peugeot has placed a second reed valve in the crankcase that allows air to escape into a chamber, which is then used to assist the air for injection.

Chrysler and Subaru have both developed two-strokes that stray further from the traditional two-stroke concepts. Rather than use the crankcase as the scavenging pump, they both use a belt-driven blower or supercharger to scavenge the cylinders. The crankcase remains a wet sump design like most automobile engines.

Transfer ports carry the air to the cylinder and the piston handles the valving of the ports. In Subaru’s design, an exhaust port in the cylinder is opened and closed by the piston, but just downstream of the port is a rotating valve that boosts the cylinder charge to more than atmospheric pressure. Air assist isn’t needed because the 1,000 to 1,200 psi fuel pressure rating automatically atomizes the fuel as it leaves the injector nozzle.

The biggest, most complex and heaviest of the conceptual automotive two-strokes is Toyota’s design. The engine is basically one of the company’s dual-overhead cam, four-stroke engines converted to run a two-stroke cycle. The camshafts run at crankshaft speed and air is delivered to the intake valves through a supercharger. Fuel is added through a high-pressure, direct-injection system. An in-line, six cylinder, 244 cubic-inch version of this engine is said to produce torque equal to GM’s 454 V8.

The motor vehicle industry has invested in a lot of two-stroke development and it’s not done. The success of the low emission two-stroke engines of today will suggest what will happen tomorrow. Will we see new two-stroke designs take over in the dirt bike market again? Will new two-stroke designs power ATVs again? Will Yamaha adapt its outboard HPDI system to snowmobiles? Who knows?

What I do know is that the new, clean two-stroke engines of today outperform the four-strokes in almost every category of performance with less weight and fewer complex, moving parts.

What is the EPA requirements for the 2 stroke producing 70 HP @ 5500 RPM 2 cylinder carb and a 3 cylinder producing 110 HP @ 5200RPM carb. I need to know if I want to be an OEM to produce a certain PWC. Can you help direct me to a website that can help me? Thanks Jeff