Summer Snowmobile Repair: John Deere Trailfire Edition

In Minnesota, the home of Snow Goer magazine and its staff, the weather has finally taken a turn toward summer. Temperatures are forecast to eclipse the 90-degree F mark on Friday, I was finally able to hit the trail on my dirt bike on Saturday and I played my first round of golf this season on Sunday. Despite those wonderful summertime distractions, I’m still working on snowmobiles.

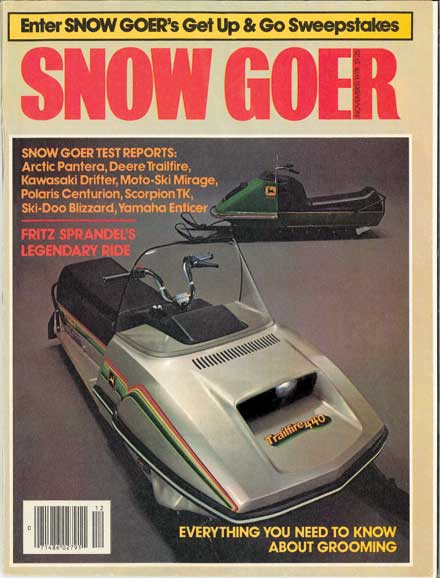

Caving-in to pressure from a group of buddies (we have a Facebook page!) to buy a leafspring snowmobile last fall, I bought a pair of John Deere Trailfire snowmobiles; a 340 and a 440. I had a ton of fun burning around on my 440 leafer early last winter. It started easily and ran OK, but it wasn’t a strong runner. I double checked the jetting and compression, but by Christmastime I knew my 440 Deere was in fact sick and it would best be left in my buddy’s barn until I could fix it, and it’s sat there ever since. (Thanks, Tom!)

While my 440 “kind of” ran, the Trailfire 340 never ran well enough for me to ride it. And after tearing into the 340 this spring, I’m sure my 440 suffers from the same ailment: bad crank seals.

When I tried to get the 340 to run for a big vintage ride in January, spark from it was blue, fuel flowed and each cylinder had 130 pounds of compression. Jetting was correct, too, so it should’ve ran OK, but instead it didn’t have enough power to drive out of a wet paper bag. Closer inspection one day revealed that the crank seals were shot, which allowed the engine to pull in air and lean out the air-fuel ratio so much that it was too lean to make power. Fortunately for me, the engine didn’t burn down on my test rides. I’m not sure I was so lucky with my 440 because it shut down on me twice one evening during my 3-mile ride to Tom’s house.

I figured I’d be able to flip over the 340 engine on my workbench, split the cases and slide new seals on each end of the crankshaft and be on my way. But the seals were so far gone for so long that the bearings were shot, too. The crank needed a rebuild.

I had the 340’s crankshaft repaired last month and I’ve re-assembled the bottom end. Now that I’ve gotten new circlips for the pistons, I can put the top end together, bolt the engine into the chassis and get this “implement” out of my way for the summer, or, to make room in my garage for my 440 to undergo the same surgery. Summer most certainly is a great time of the year to work on sleds, because I only get busier when fall rolls around.

Where did you get parts for that?

How do you remove the seat on a 1979 JD trailfire 440- so that I can remove the gas tank to clean it out ??? Thanks