A Hypershift clutch kit for the Arctic Cat Sno Pro 500 includes Speedwerx’s exclusive H5 alloy springs for the primary and secondary clutches that the company says offer the benefits of titanium at a cheaper price. The kit also includes mass-adjustable weights and a stickier-than-stock Arctic Cat belt.

With the clutch kit installed in our 2011 Sno Pro 500 by Speedwerx, we hit the trail expecting a stronger pull down low and through the mid range, but the engine felt sluggish and peak RPM was down about 300 rpm from where Speedwerx said it should run. We removed mass from each flyweight in the primary, but that didn’t improve peak engine speed, so we dialed up Speedwerx and asked what to do.

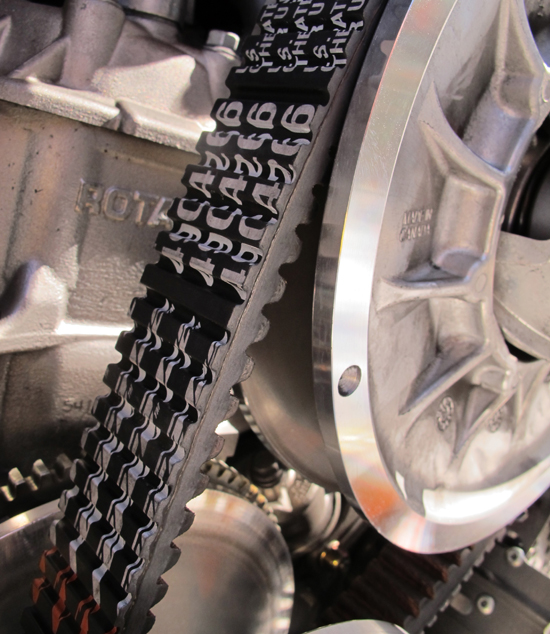

A cool feature of TEAM Industries roller clutches, which are a standard part of the Sno Pro 500 drivetrain, is the helix has multiple ramp angles. We pulled the clutch off the jackshaft and moved the helix from the stock 40-degree set of ramps to the 38-degree ramps. To understand why this reduces the load on the engine, think of it like pushing a ball — the roller — up a hill. Switching to a flatter hill — the ramp — makes it easier for the clutch to shift out.

With changes made in the driven clutch, the engine peaked out at 8000 rpm at wide-open throttle, occasionally hitting 8050 rpm on long, wide-open pulls. The sled sounded better and felt freer to roll through the whole power band. Compared to stock, it was jumpier out of corners and more responsive on the low end. We picked up about 7 mph on the top end over the original Speedwerx calibration.

Clutch engagement was 1000 rpm more than stock. With peak engine speed set at 8000 rpm and occasionally creeping to slightly more than that, there was a narrow power band. It’s hard to believe that a little 500cc two-stroke engine can make a snowmobile seem harsh, but this one was. It slammed at engagement, and it felt like the belt was slipping on the clutch when rolling back into the throttle at the apex of a corner.

We’ve run Speedwerx clutch kits in some of our Cats over the past few years. While they’ve unquestionably improved acceleration and top speed, all of them have been more harsh than stock at clutch engagement. This gives the powertrain a more aggressive feeling that’s fun when you’re in a punchy mood and riding aggressively, but it can cause track spin and faster wear to the belt and clutch parts.

An advantage of clutch kits is that they provide a custom setup to suit rider weight and traction that sled manufacturers just can’t offer. Most clutch shops have tech lines to help dial in a machine. If you buy a clutch kit and the setup isn’t quite right, be sure to take advantage of the company’s full service. We did, and it took what could have been a disappointing modification and turned it into a setup that made our sled quicker.