EDITORS NOTE: Each year, Snow Goer kicks off a new season with Q&A interviews with designers and engineers, taking readers deeper into the development of new technology. This article appears in the October 2019 issue of Snow Goer. We’re currently working on our 2021 Tech articles on this year’s technology. Subscribe to get the information delivered to your home!

There’s an old American saying that goes, “to play hard you must first work hard.” Apparently Ski-Doo engineers in Quebec and Scandinavia do not abide by the same cultural adages when they created a sled capable of doing both within the same trip.

Well established within the utility sled segment, Ski-Doo official estimate its Expedition, Skandic and Tundra lineups comprise 70 percent of the current market – but to them, that only means there’s 30 percent left not using their highly capable machines.

Three new models – the Expedition Xtreme, SE and LE – were offered for model year 2020 in the REV Gen4 platform to the delight of many who have jobs to do, but also want to play in some powder after (and possibly briefly before, too). All three will run on 20- by 154-inch tracks with a new high-low-neutral easy-shifting transmission, plus push-button reverse. From that baseline each undertook its own customized tweaks in order to offer the machines for each intended market.

We spoke with Ski-Doo product manager Jimmy Cote, an avid utility sled rider his entire life after growing up in northern Quebec, to discuss the different changes made for the new season.

SG: First off, why did Ski-Doo place such a specific focus on the utility segment with its Expedition lineup? Was there something you felt was missing, or specifically needed tweaking?

Cote: “We are dominating this segment by far. Our market share has continued to increase over the past few seasons, not only in North America but in Scandinavia as well. But this is not a reason to ignore the segment; the utility segment has been one of the fastest growing in the last 10 years, mostly fueled by the Expedition and the 900 ACE engine. We recognize that we own this segment, but we’re still very committed to those riders.

“The Ski-Doo Rev XU platform that launched in 2010 has been a strong success. However, the platform was 10 years old, and did not have a half-life refresh like XP platform. The Expedition deserves the same level of technology and refinement as the Renegade, for instance. We thought it was the right time to upgrade the models.”

SG: How long has this project been in development, and what were the early design goals? Were there specific targets related to weight-carrying, towing, flotation, etc., or other categories?

Cote: “When we started to work on the REV Gen4 around 6 years ago we knew that we would integrate the four-stroke and Expedition in that platform. So technically it started that far back, but that last 3-4 years have really been dedicated to it. The project was based on a survey we did. It started with field observation – we went riding with utility riders in Alaska, Scandinavia, Russia (a few years ago) and in Quebec, where we are very close to a great piece of the market.

“Along with the field observation, was a huge quantitative survey of those markets because we wanted the Expedition to meet the most important needs of the consumer no matter where they were. Some of our engineers are utility riders too. We try to leverage every channel we have to listen.

“I grew up in northern Quebec, in the heart of the utility market. I’ve been riding utility sleds since I was 5-years-old. I started on an Alpine snowmobile, then graduated to a Tundra I, and then a Tundra II when I was 13-years-old. My father had the VK540 when Yamaha was really strong in the utility market in the early ’90s, so I rode that also. So I have a good idea what the needs of this consumer, are also.

“All this together – testing, listening and surveys – gave us the exact ideas of what we needed to improve. Our goal was to bring the Expedition to the level of refinement, quality and technology of the Rev Gen4. Contrary to the former Expedition, which was a developed from a Skandic, this was truly a spin-off of the Renegade. It was developed with the changes needed for the utility rider – the heavy-duty aspect of utility riding. Development was a strong collaboration with our Scandinavian colleagues; it was really a team effort.

“An analogy is the modern SUV – 15 years ago they were built from a truck, and they were rugged and rough riding. Today if you look at the 2019 SUVs they are very comfortable like a car, they have all the technology you want, but still have towing and utility capabilities.”

SG: What were some of the big challenges encountered along the way?

COTE: “The biggest challenges were towing performance and cargo capacity. Our reference was the Rev XU, so one of our main focuses was to keep dimensions as narrow as possible without losing the under seat storage and fuel capacity. We wanted more space in the rear, and to bring the rider closer to the front for more comfort, while keeping good fuel capacity and space under the seat – all this was a challenge. This was to meet the specific needs of consumers; some of their needs, depending on the region, are quite different. That’s where our multi-LinQ plate and LinQ accessories were a solution to meet rider needs.

“Another focus was noise and vibration. We need to have the rugged aspect and towing capacity, but the Noise, Vibration and Harshness (NVH) had so much opportunity to improve, and so we targeted that from the beginning. Most of the time the NVH comes from three main elements – the engine, the gearbox and the track.

“Attention to reduce the NVH was focused on the gearbox and the track. The focus for the Expedition was on the transmission and the track, I’m not mentioning the engine because we started from the Renegade, so the engine and the engine bay were already covered.

“The new transmission is about 50 percent quieter, and the track is about 33 percent quieter. To reach that noise level for the transmission is quite the challenge. With the track, we had a little more experience [due to sound reduction steps taken earlier] with the Grand Touring.

“For the track we worked with our Advanced Technology Center at the University of Sherbrooke testing many concepts for the Grand Touring so we leveraged that into the Expedition. It was a challenge, but I’m really proud of what our engineering team did.”

SG: What were some of the biggest challenges in the utility-focused elements of this sled development to overcome? In what areas do you feel like you’ve set new benchmarks?

Cote: “The biggest challenge was to deliver the best towing and cargo capacity. Having a strong tunnel was a challenge we overcame.

“Another area of focus was needs-specific for utility riders who go off-trail and need flotation and reverse capability, because if those utility riders go in the woods and get in a bad spot, they need to go forward and backward forever until they get out.

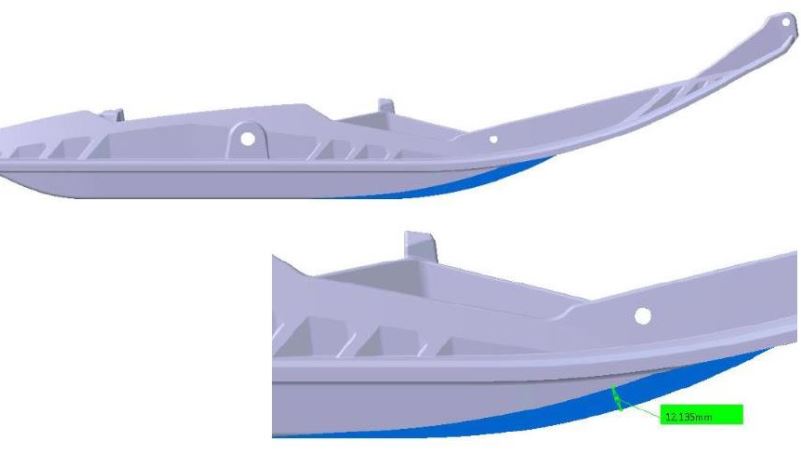

“So we wanted to improve the performance of the ski, which was a challenge because the DS2 was already good. But sometimes when you improve one aspect of a sled, something that used to be good falls behind so you need to keep that level of balance between each system. At one point it became clear that we had to improve, so the Pilot 7.4 was created.

“Improving reverse capability – that was the first element [of the ski]: the rear is more angled to improve its reverse capability. Next was better floatation and then trail cornering. Because Expeditions go off-trail we calibrate them to have a lot of transfer for deep snow. But having a more aggressive ski contributes to good performance for on-trail cornering, and when towing.”

SG: Does the high capacity battery, cooling system, subtransmission, etc, add any extra weight? And was a weight target important to this project?

Cote: “Reducing the weight was a top priority from the very beginning – we shaved up to 30 pounds on some packages. We were able to save weight in almost every system.

“The cooling system reduced weight, because it uses the same heat exchanger as the Summit or trail REV Gen4. The gearbox is a place where we saved a lot of weight, too.

“The only place where we gained a little bit of weight was in the rear suspension because we wanted to improve the durability and reverse capability, especially with the expansion of the Xtreme sub segment – those riders who use it a little bit more like a Summit, so they jump and do things that Expeditions haven’t done until recently.

“The new easy-shift transmission was also a key area where we saved weight – the former transmission was designed by a third party, this time we designed it as a shared program between [the sister Lynx brand factory in] Finland and Valcourt engineering. The new concept is lighter, quieter, more durable and easier to use for the customer.”

“The new easy-shift transmission is quieter because of the reduced parts – there are fewer gears. Transferring the energy to the track is not solely gears like the Synchromesh, but a more typical chain that reduces noise, makes it more user-friendly and lubricates the overall transmission as the chain transports the oil to the top of the transmission.

SG: The limited track noise/howl when riding the 2020 Expedition Xtreme was amazing to our staff. What steps were used to take away the noise normally associated with huge tracks, and why was that important?

Cote: “We have three ways that reduce the noise. First, is a softer rubber strip running under the idler wheels. Where the wheels are touching the track, the rubber is smoother and this reduces noise big time. Second, it is ribbed on each edge – like a 2019 Grand Touring. This reduces track vibration and noise. Finally, you see an opening in the center of the track. A track is like a drum resonating into its cage, but if you open or place holes in the drum, it will not resonate like it used to be because the air is allowed to release. Putting a hole in the track eliminates the resonating and at the same time, saves weight.

SG: What testing went into determining its 1,200-pound tow rating? Do you test beyond the towing- and weight-carrying limits, knowing that your final customers will?

Cote: “When we rode with customers and from the survey we asked what they needed, and arrived at a target capacity. A good survey isn’t about asking the customer what towing capacity they want, but instead what they need to do and from there our product engineering figures out the best tools to achieve it.

“The same goes for cargo and capacity – we determine this by understanding the top-10 items the utility rider wanted so we knew the load it would put on the tunnel and how strong we would have to make it.

“It was tested extensively with more weight than the intended specs in the toughest possible conditions. The standard factory towing capabity is 1,200 pounds, but we always tested with several hundred pounds more. When we did these tests always looking for a perfect score – we’re not looking for 90 percent success, but 100 percent.”

SG: What went into adding the Multi-LinQ plate? How early-on in the project’s timeline was there interaction between the traditional sled designers and the accessories designers?

Cote: “These riders want to configure their sled for what they want to achieve. Some want to go hunting, some want to cut firewood, go trail riding or fishing – how can you build a sled that meets all those needs?

“Everyone has different needs. We had to find the core – what does everyone need – and how can we adapt to the needs of each? That’s where the multi-LinQ plate became the key feature to deliver this benefit. The rider can configure all Gen4 accessories to meet their needs – and change as often as needed. Also there were 25 new accessories developed specifically for the Expedition.

“Accessory designers were involved since day one – everything was a matter of collaboration. This is the largest offering of accessories for the utility segment ever and will only expand in the future. The chainsaw holder, ice auger and gun boot are some of the Expedition-specific accessories that will be very popular.

“Another aspect of the multi-LinQ plate is size – the 600 square inch capacity – is 67 percent more than the Rev XU which was previously the largest offered. The cargo box is also 135 liters of fully configurable storage, and has been designed with the LinQ system. It can also be removed.”

SG: Was the high/low/neutral easy manual shifting transmission the result of rider preference or functionality? A mixture of both?

Cote: “A mixture of both. They want to be able to changes gears easy – no one wants to fight with the transmission. This is the level of refinement the utility rider is looking for.

“If you think about the F150 or Chevrolet Silverado, those kinds of buyers are not only looking for a truck that is rugged and has all-wheel drive – they are looking for technology and comfort that will make their life easier. These key features create a competitive advantage that would make the utility rider love their sled. Having an easy to use transmission was important, and we worked hard to deliver it.“

Editor’s Note: Every Snow Goer issue includes in-depth sled reports and comparisons, aftermarket gear and accessories reviews, riding destination articles, do-it-yourself repair information, snowmobile technology and more. Subscribe to Snow Goer now to receive print and/or digital issues.