This is one of the best times of the year. We’ve already transitioned from summer into fall, and now we’re slowly sliding from fall into winter. The cold nights, a coating of frost in the morning, getting outside marking trails and getting ready for another snowmobile season are all wonderful elements of this season. Another important thing that should be on your checklist is to make sure your sled is ready so that when the first rideable snow falls, you can pull the cord and go. Whether you do the work or leave it up to a shop, here are three snowmobile pre-season tips.

1. Bearings Early season bearing failures are common because snowmobiles sit stationary all summer while the bearing and its race picks up corrosion. Once the bearing starts to roll again, the corroded bearing and race heat up and either damage the seal and cause loss of lubrication or the heat draws in moisture and causes complete failure. To prevent this, grease the bearing — if possible — now before you hit the trail, and be sure to do it next spring before storage. Listen for noise and wear, replace them if you can hear a lot of grumbling or can feel roughness.

2. Carburetors If a carbureted sled won’t idle, the sled needs some attention, otherwise it could suffer damage that is expensive to repair. Start your machine and evaluate its running quality. It should idle smoothly and consistently within about 15 seconds. If it won’t continue to run without your help, either by running the choke or primer, the pilot jets in the carburetors are probably plugged, and if those jets are obstructed, the main jets likely are, too. A plugged pilot jet won’t usually cause damage, just poor low-end performance, but if fuel can’t flow through the main jets — which comes into play above half throttle — the fuel/air ratio will be too lean and cause a burndown. Just like that, you’re out a few hundred bucks that it takes to rebuild it.

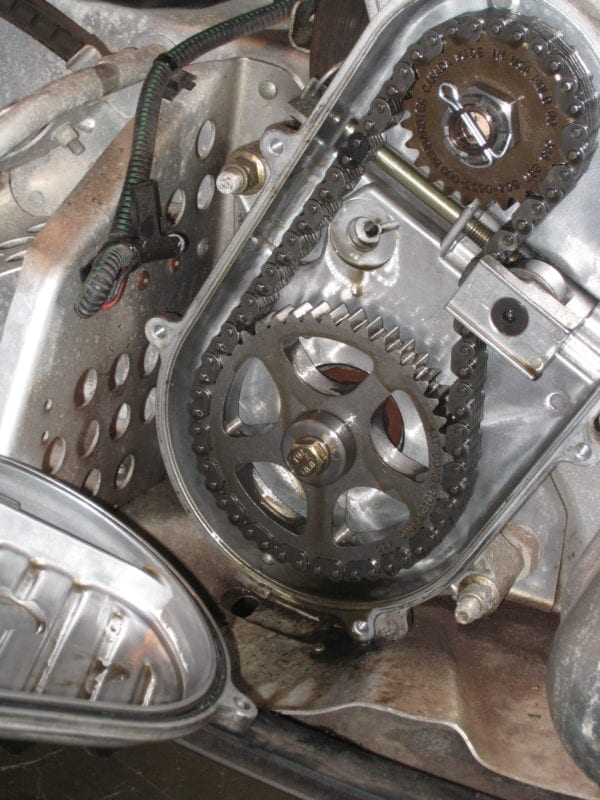

3. Chaincase You wouldn’t drive your truck if it didn’t have transmission fluid, and you certainly shouldn’t drive a snowmobile without lubrication for its drivetrain, either. Chaincase oil might have leaked out over the summer months, leaving the chain and sprockets dry, and without oil in the case to cool and make the parts slippery, they probably won’t last more than a few miles. Chaincase oil should be changed annually because it breaks down due to heat, and it can even absorb moisture caused by the hot/cold cycles. You can get away with simply draining and refilling the oil, but it’s best to remove the chaincase cover and inspect the parts for excessive wear or damage.