One of the more frequent questions snowmobile owners ask is what two-stroke oil they can use in their sled. The short answer is “a lot.” Though there are many oils competing for a portion of your paycheck, sorting through the options and prices of the oil market can be mind-boggling.

We typically use the manufacturer’s oil during engine break-in, but after that we usually start filling reservoirs with aftermarket product. That often leaves us with the “What oil?” question to ponder, too.

We spent time in the lab with the manufacturer of Arctic Cat, Polaris and Ski-Doo snowmobile oils to get familiar with the production process of manufacturer’s oil. During our visit, we learned that oil isn’t just oil anymore.

Rigorous Testing

There are numerous goals specific with snowmobile two-stroke injection oil. The oil must have cold-weather properties, such as a low pour point. The pour point is the lowest temperature at which a fluid will move due to the force of gravity. Snowmobile pour points are essential for both filling a sled’s oil reservoir and ensuring adequate injection during operation in cold weather. Proper chemistry, high temperature viscosity — to ensure adequate lubrication — and corrosion protection are other key objectives for oil to meet.

Todd Matvik, a manufacturer lubricant development chemist, said when a new oil formulation is in development there are preliminary dyno tests performed with multiple oil candidates in multiple dyno and engine combinations. A baseline oil is used as a reference point. The next step in this early exploration phase is a series of screening dyno tests to identify the oil candidates using small engines for data acquisition.

The tests quantify port blocking tendency, smoke rating, lubricity and total engine detergency tendency to determine the good candidates. It’s a fine line identifying good candidates. “Even short detergency tests — on the order of 6 hours — exhibit stark differences in cleanliness patterns when the optimal formulation is not used,” Matvick said.

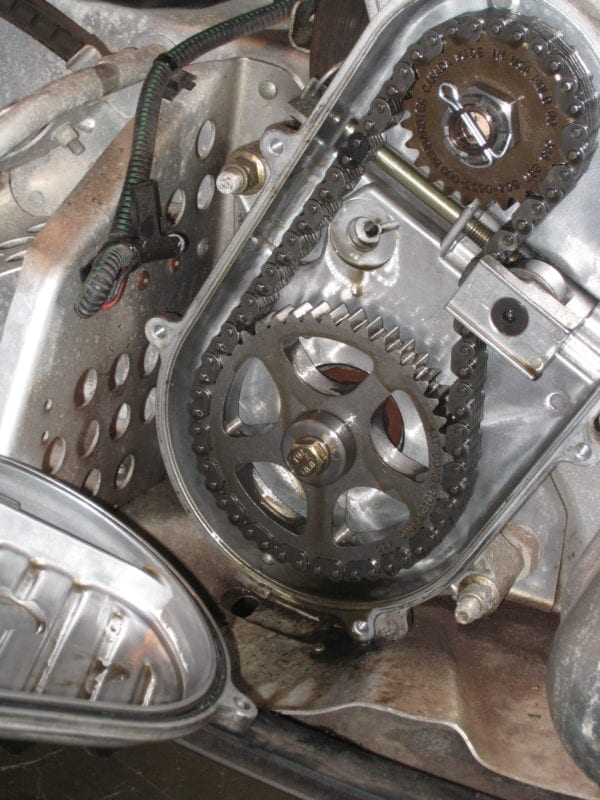

Once the compound is determined for a manufacturer’s oil platform from the best candidates, the manufacturer generally chooses the engines to be evaluated in initial dyno testing. This decision is based on the best fit to its fleet as it relates to the most-demanding applications and engines with special lubrication requirements.

Initial engine dyno testing is a screening process to determine how well the small engine data correlates with the manufacturer’s engine. The screening phase is anywhere from six to 20 hours, and data is captured for smoke, smell and detergency tendencies. The engine is also disassembled to examine wear. If the oil passes the screen tests, it undergoes lifecycle testing.

The new oil formulation is tested extensively on a dyno with a rigorous, accelerated duty cycle designed with test parameters from manufacturer engineers. A manufacturer also routinely conducts dyno tests of its own.

“Prior to field tests, an oil must pass lab and dynamometer tests, which simulate field conditions and life cycles,” said Donn Eide, Arctic Cat Engine Test and Design Manager.

Dyno tests are helpful screeners and accelerate the test cycle, but field testing is another critical phase. “A new engine oil must prove itself in every possible field condition,” Eide said. “We conduct field testing in current engine platforms and often in next generation engine designs, from the Minnesota trails to the high mountain elevations in the Western U.S., from mild winter conditions to the dead of winter at 35 below [zero]. After thousands of hours of operation, we have to be 100 percent satisfied with an oil’s performance before it is ever sold to our customer.”

Polaris ran VES [oil] more than 680,000 miles in the validation process before it was approved, according to Joe Laurin, Polaris’ manager of powertrain validation.

“We needed three full years and spent more than 300,000 miles on the dyno and in the field, developing and validating a new two-stroke oil,” BRP’s Power Pack Project Manager Frederic Desjardins said. “The main challenge in our most recent oil development project was to have an oil that will not only protect today’s high tech engines, but also reduces the smoke and smell significantly. Understanding the time and the effort we spent together with our lubricant partner on that program — and knowing exactly what our engines’ needs are — [using] another oil brand will be a pure guess [at results].”

Specific Recipes

While the process of oil production might be much the same with other oil companies, a sled’s owner’s manual that pushes its own oil brand seems to be about more than just the manufacturer’s bottom line. All oil plays a critical role in engine durability and run quality, but a manufacturer’s oil is tested extensively in the field to ensure run quality and cleanliness and engine durability.

While the process of oil production might be much the same with other oil companies, a sled’s owner’s manual that pushes its own oil brand seems to be about more than just the manufacturer’s bottom line. All oil plays a critical role in engine durability and run quality, but a manufacturer’s oil is tested extensively in the field to ensure run quality and cleanliness and engine durability.

The fact is that a factory-spec oil composition is different than oils available in the aftermarket. In fact, Arctic Cat’s APV oil is “drastically different” than Polaris’ VES Gold oil, though both oils have the same certification, are specified for use with exhaust valve engines and are synthetic based.

A chemist might best describe “drastically” different, but one manufacturer might prioritize heat management in its oil while another manufacturer’s engine might need better lubricity. Different priorities based on engine design creates an oil that is, ultimately, a specific recipe.

As a general rule, the most current oil standards, JASO-FD and ISO-EGD, are good because they protect consumers from unscrupulous oil manufacturers.

The certification of a lubricant consists of four engine tests: smoke production, port blocking, lubricity and overall engine detergency, Matvick said. “Although good standards, [a manufacturer’s] oil goes many steps beyond that and does not rely on the extrapolation of data from these tests to predict actual field performance.”

Impurities

In order to make spec oil with tight tolerance, the compounds used in the final, blended product must be free from impurities. Chemists have to test the base compounds to make sure there are none. Though a rare occurrence, the oil manufacturer we visited said it has rejected entire rail cars of oil-base compounds because of contamination. Impurities such as moisture or glycol, improperly reacted detergents and dispersants and other additives are the most common contaminants that cause engine failure.

FAQ

“What is the minimum standard I should seek with oil?”

The first thing you need to do is abandon any remaining notion of TC-W3 oils. That is a carry-over marine certification that has little relevance to snowmobiles. Although suited to deliver clean engine operation in two-stroke watercraft and outboard engines, the lack of ash-containing detergents leaves a gap of protection in hot areas of the engine. JASO-FD and ISO-EGD standards address proper lubricant selection for today’s non-marine, high-performance two-stroke engines.

“Is there any other oil I can use in my new Ski-Doo E-TEC?”

In this case there is a clear answer: NO! Because of the complicated calibrations of Ski-Doo’s new electronic oil pump, the fuel to oil ratio gets into the range of 120:1. BRP’s Frederic Desjardins said, “BRP snowmobiles and Evinrude outboards use the same E-TEC technology, but the oil requirements of the engine families are extremely different. We quickly realized that we needed to develop two different oil blends for two different field applications.”