Do you know the difference between torque and horsepower, and how they affect the performance of an engine — including a snowmobile engine? Snow Goer’s own TJ Krob, author of the Snowmobile Science column, provided this detailed background in the January 2017 issue of Snow Goer magazine. His columns normally don’t include this many formulas and equations, but in every issue Krob provides a scientific or engineering background on something related to snowmobiles. To regularly read TJ’s column and all of the other reviews, comparisons and features in each issue, subscribe to Snow Goer magazine today.

The Relationship Between Torque & Horsepower

One Can’t Come About Without The Other

By T.J. Krob

Snowmobiles, golf carts, motorcycles, weed whips and countless other powered devices rely on engines to make them move or do their work. The history of engine design is long (and getting longer by the day), but after examining how their construction varies, one thing remains the same – they all produce power and, therefore, torque.

Original engines made power from steam, and now there are monstrous diesel engines, two-stroke gasoline engines with variable exhaust valve openings, four-stroke engines with variable valve timing, variable compression ratios and cylinders that don’t fire all the time, among other designs.

Talk to most snowmobilers about sled engine performance and the conversation will likely turn to the term “horsepower” – as in, how much horsepower does this or that engine make? Other times, though, an engine will be described as being particularly “torquey” in the way it performs.

But what exactly do those terms mean, and how are they related to each other?

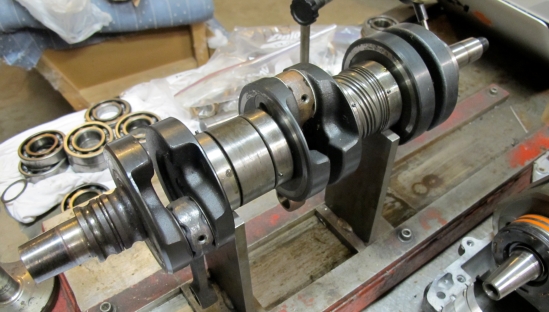

Well, technically speaking an engine doesn’t make horsepower without making torque – it makes torque via the twisting force exerted by the pistons/connecting rods applying rotation to the crankshaft, and horsepower is merely a calculation of that torque figure, which is multiplied by a formula that includes the engine’s operating RPM. To understand how that comes together, we must dig into some physics books – this is going to get nerdy, but stick with me if you’re curious.

Important Factors

Physics contains important governing factors and equations for how power (P) and torque (T) are calculated. First, there is the force (F) quantity measured in Newtons (N). Force is an exertion of pull or push interaction between two bodies with mass (M) that causes one to accelerate (A) in a given direction under the equation: F = M x A. Gravity is the most prevalent factor where my 63-kilogram mass is pulled toward the ground at a specific rate, exerting 612.5N of force on the earth.

Second there is work (W) measured in Joules, which describes a force acting over a displacement (D) calculated by W = F x D (in the direction of the force). Examples of this include lifting an engine from the ground onto a workbench – I exert force upward and displace the engine by the height of the bench. However, if I push against a wall, which makes me tired, I have done zero work on the wall because my horizontally directed force did not move the wall in the horizontal direction. This is a great time to discuss the term “torque.”

Torque is a force that acts about an axis in a circular direction, such as on a wrench with a long handle imparting work to the threads of a bolt. Pushing that wrench with given force at a distance away from the center of the bolt produces a torque value of T = F x D in units of Newton-meters.

Energy is another important physics point to make here because a change in energy is a combination of potential energy, kinetic energy, plus work. And the final term – and what we’re after – is power (P). Power is the measurement of that work done per unit of time, so P = W/T in units of Joules per second, or Watts.

Turning Horsepower Into Torque

In 1782, inventor James Watt (for which the Watt unit is named) examined a walking horse that could turn a 12-foot radius mill 144 times per hour pulling with 180 pounds of force. Watt calculated that the horse could create 33,000 foot-pounds of force every minute, a calculation that has the standard unit value of 1 hp, or 746 Watts.

Now we can bring it all together! So torque is F x D, while power is F x D/T (think of torque as work, and power as the result of torque’s capability of doing additional work), so we should be able to pull these into the same equation with some conversion factors to pair the linear distance travelled in the power case with the rotational distance of the exerted torque case.

Engines rotate at a speed of omega, or as our tachometers display: RPM. Using Imperial units instead of metric units within a power calculation can lead to problems walking through the steps of unit conversion, but most people are familiar with the term “foot-pounds” to quantify a torque rating.

And since we’re talking about rotational forces, our old friend “pi” is involved. Pi is 3.14159. Sticking with these Imperial units, horsepower can be calculated as a combination of the torque value, the rotational speed of the crankshaft and an extracted constant incorporating the 33,000 foot-pounds of force per minute with the number of radians in one revolution of the crankshaft. This equation falls out as HP = (T x RPM)/(33000/2pi); or further simplifying, HP = (T x RPM)/5252. So power and torque cannot occur without each other and are directly related. Neat!

Doing the math, two 160 hp snowmobiles that run at 8200 RPM will have the same torque rating. Solving for torque, 160 HP = T x (8200/5252). Do the math and that engine makes 102.478 foot-pounds of torque. However, if a manufacturer can design an engine to create more torque at the same RPM, the horsepower inevitably goes up. So, if that same engine listed above makes 105 foot-pounds of torque, it creates 163.93 HP. Design the engine to make 110 foot-pounds of torque at 8200 RPM, and you’ve got a 171.74 HP engine.

Ultimately, if designers or tuners want more horsepower from a given engine, they either have to increase the torque or increase the operating RPM, or both.

What else does this mean inside an engine? Well, for starters, the governing equation requires that the power and torque curves of an engine plotted over engine speed always be equal when a tachometer reads 5252 rpm.

Comparing power bands of differing vehicles is also incredibly enlightening. For example, a 1000cc, four-cylinder sport-bike engine might exert 180 hp to the wheel at 13,500 rpm. How much torque is this?

We can reference our equation from above and calculate T=5252 x P/RPM or 70 foot-pounds of torque at that given engine speed. Compare that to a powerful diesel engine that will pull 1,300 foot-pounds of torque at 2300 rpm and make 569 hp – quite the stark contrast not only in magnitude, but also note how the operational values have swapped for which is the greater value. The sport-bike engine had a higher horsepower value at its optimal operation, while the diesel truck’s engine ran much harder having a greater torque value than horsepower value.

For most two-stroke snowmobile engines, a manufacturer might publish an output of 150 hp at 8000 rpm. A torque number here would be 98.475 foot-pounds.

At which RPM an engine produces maximum thrust is purely at the discretion of the engine builder and he or she must know the intimate relationship of compression ratio, stroke, bore, port placement or valve mechanics, etc. to produce a useable powerband. Luckily for us, factories have been creating stout mills and placing them under plastic snowmobile hood for years to provide us with a great ratio of torque to power, and now you hopefully understand how that all happened.