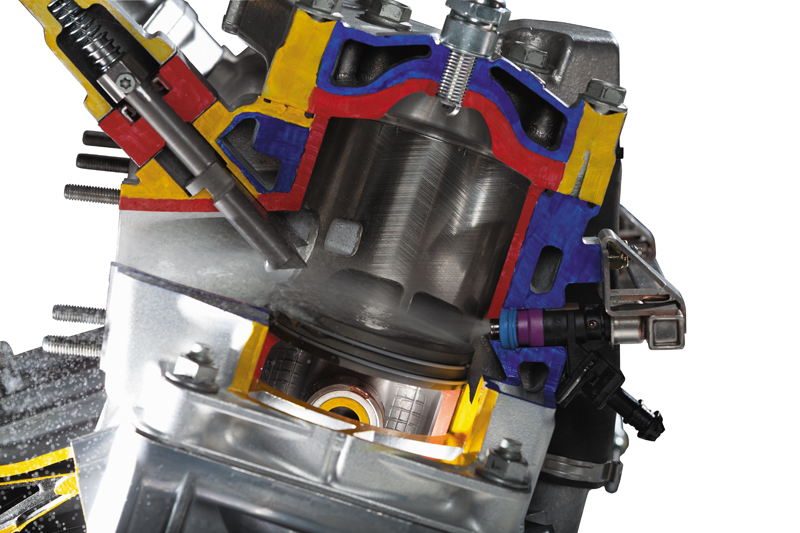

In case you haven’t heard the word, Arctic Cat has a new snowmobile engine for 2014. The difference between this engine and previous Cat launches? This one is all Arctic Cat designed and manufactured – the first Cat-developed two-stroke snowmobile engine in the company’s long history.

The engine is a 599cc, liquid-cooled, semi-direct injected twin that features a lightweight design and many unique features. Foremost on that list is the Dual Stage Injection (DSI) system that injects fuel on top of the piston, and through a slot in the side of the piston.

To learn more about the process of developing this engine, Snow Goer traveled to Thief River Falls, Minnesota, to meet with Donn Eide, the engine test and design manager; Greg Spaulding, the ground leader in charge of two-stroke design and high-performance development; and Joel “Joey” Hallstrom, the snowmobile product manager.

To see the full story on this engine and its development, including technical details of the engine, pick up the October issue of Snow Goer magazine. Below is the text of most of our discussion with Eide, Spaulding and Hallstrom. The first couple of minutes of our discussion were lost due to a glitch with our recorder.

SNOW GOER: What were your targets when designing this particular powerplant?

DONN EIDE: Initially, we targeted the Tier 3 EPA emissions standards, which is 2012, and at same time [we targeted] improved fuel economy. We wanted to retain the cost and weight and simplicity of the current batteryless EFI system

SG: Obviously you also have to remain competitive in the 600 class vs. your competition. Was there a horsepower target or some other way of measure competitiveness?

EIDE: We started on the F6 600 engine, and saw improvements. Then we said, OK, now let’s try the system on the more hyper 600 SnoPro race engine – As you know, the Sno Pro race type engine is more high strung, and it gave the wall injector a good test. We said, “Let’s try the wall injector on that and see if we can make a good consumer package” and it did. So basically we were able to take the high performance race engine and make it clean running and fuel efficient at the same cost and weight as what it is currently.

JOEL HALLSTROM: So the 600D is the Suzuki 600 EFI – from the F6. And then there’s the Suzuki 600 race engine, which is still carbureted, but they adapted this system to that engine.

EIDE: That helped prove its benefit and potential. That was the spring of 2010, when we ran the first 600 Sno Pro engine with DSI.

SG: At the same time that this was all going on, obviously those of us outside of the Arctic Cat walls didn’t know what was happening in terms of your relationship with Suzuki and your future powerplant plans. When you guys started this project, did you know this system was going to end up on YOUR Arctic Cat exclusive engine, or was it something you were going to develop for whichever engine was available in the future?

EIDE: When we first started developing the fuel system, we did now know at that time that it would be on Arctic’s first engine. The first time it became known or looked like we would be applying it to an Arctic engine, was in about the spring of 2010, after it was tested on the Sno Pro race motor.

SG: So from that point forward, how different is the development of this entire engine and fuel system from what you guys had previously done, when developing ZRT engines or the F7 engine or whatever? To an outsider, we didn’t know how much of those engines was Arctic Cat vs. Suzuki. Was Suzuki just the manufacturer and Arctic Cat the developer, or isn’t it as simple as that?

GREG SPAULDING: You have to look at it two levels. You have design and you have development. The difference with our new Arctic Cat engines is that we do both of those 100 percent. In the past, we would work jointly with Suzuki on the design. So, for instance, Joey [Hallstrom] in marketing would say, “OK, we need X for a motor – this is what we need because this is what the customer wants.” So that would be the directive, and then we would start communicating with Suzuki to work up a plan to design an engine to meet those parameters.

So we’d work jointly, but Suzuki would do the design. Obviously, they have enough experience to design a motor with the strength and structure, and we were fortunate enough to get to work really closely with them. So then we’d get the design and they would prepare typically six sand-cast prototype engines, and they would ship them here. Then we would develop those engines – develop them in the sense that, is the cylinder port layout correct? The combustion chamber, the piston profile, all the exhaust development, the intake development, the mounting – that’s all part of the development, because it’s all part of a package. The difference now is, the design portion which we would do jointly with Suzuki, now we do 100 percent here. And then we develop that engine as we did in the past.

SG: You guys have always had very strong motors, but were there ever communications problems or any back-and-forth the Suzuki in Japan that you’re now able to avoid with your new arrangement? Any hurdles over the years?

EIDE: It got better over the years because you could email back and forth – before we were writing ideas on a piece of paper and faxing it. But overall, we had a really good relationship over the years with [Suzuki designers]. We became friends. Both groups developed great friendships that will last forever.

SPAULDING: And they would come here and stay for a month or two at a time. And Donn, I don’t know how many times he’s been over there over the years, and I know Joey certainly was.

SG: With this new El Tigre engine, obviously there’s a lot new here – certainly the injection system, but the reeds, the crank, the lighter weight and more. But you also maintained a lot here that Cat customers are used to seeing: the power valves, the laydown design, etc. Is that just a function of being a layout that you just knew worked or were comfortable with, or are there other reasons?

SPAULDING: With the laydown design, a lot of people have asked that, and the answer is, “Why wouldn’t we?” That thing, because of its laydown design, its shape, its crankcase, it’s inherently stiff and strong. We knew it was strong, so we didn’t want to deviate too much from that. Because of the laydown concept, we have had a very durable design – probably the most durable bottom end in the industry.

EIDE: That’s probably one of the bigger answers for when people ask why they should trust a first-year motor. Well, we took a proven design — probably the best design in the industry by far in terms of strength and durability, and we didn’t want to deviate too far from it

SPAUDLING: Even though we’ve had it for a number of years, it’s still a new design, relative to everything else. I mean, if you stand it straight up, that’s how snowmobile engines have been since the 1960s.

SG: Aside from that, it’s even the same bore and stroke. Again, did you end up there because that’s your comfort zone and it’s proven to work?

SPAULDING: Yeah, we’ve had experience with that, and therefore you know the durability of those components in that design, but also we felt that that’s a very good bore/stroke ratio for that displacement motor. That’s one of the beginning things when you lay out a motor – what are you going to operate it at, what’s the displacement, what’s it going to run at, what’s a good bore/stroke ratio? And that is a good ratio.

Are you a hard-core sledhead who lives to ride? Fuel the passion by getting Snow Goer magazine delivered to your house seven times per year for just $16.97 — that’s less than half the price of buying it on newsstands. Click here to subscribe now