Carb Float Settings

Carb Float Settings

Q: I recently purchased a 1987 Ski-Doo Stratos 503 that floods while it sits. I put new needle and seats in the carbs and adjusted the floats more than I can remember. What is the right way to adjust the float tang in the carbs? Any help you could give me would be appreciated. Thank you for a great mag!

– Jeff leverington

Oelwein, Iowa

A: You are on the right track, Jeff. An engine that floods while turned off usually has a problem with the float setting or needle and seat assembly. To set the float height, make sure the float tang is parallel to the carburetor’s body when the carburetor is held upside down and that the floats can easily slide on their posts without binding or hanging up. Did you buy high-quality needle valve assemblies? Some aftermarket needle and seats do not seal as well as genuine parts from the carburetor manufacturer. There are also different actuators on the needles and different flow rates of the needle and seat. There is a number on the part, which should be 1.5 for your sled. Confirm that you have the right number and style. Also, the needle and seat can be tested to confirm they seal. Many shops have the tool to do this.

SDI Engine Storage

Q: I read your article about how to summarize Polaris fuel injected sleds and I was wondering what source this was from. I own a 2008 Polaris 600 IQ with CleanFire Injection. I wondered how to summerize my sled last spring and my manual just said that the “engine must be fogged with fogging oil.” The [container’s] instructions offer two options: spray into carburetors while running, or remove spark plugs and spray in the cylinders and then turn it over. Your recent article says to stay away from fogging oils in these fuel-injected systems. [Instead,] you said to pour SAE 30 non-detergent oil down each spark plug hole and that this is a better way to store a Polaris engine and they do not want anything through their throttle bodies but air. Can you please provide some more info on why oil should not be sprayed through the throttle body and perhaps what source this info was from?

– Reg Guay

A: You must have us mixed up with another magazine, Reg, because we haven’t published anything recently about fogging your sled. Nonetheless, we’re happy to help. There’s no reason not to fog your sled through the throttle bodies, other than the fact that airboxes on some new sleds are difficult to reinstall. So feel free to remove the airbox, fire up the engine and spray fogging oil into the throttle bodies. Sure, you can spray fogging oil through the spark plug holes of an engine, but make sure each piston is below the transfer ports so oil can flow down through the ports to the crankshaft before you slowly pull the recoil a few times to distribute the oil. No matter how carefully you do this, this method isn’t as effective as spraying through the throttle body with the engine running. Don’t use 30-weight oil because it’s too thick and will be difficult to “burn off” when you pull the sled out of storage. The throttle bodies on Polaris and Ski-Doo semi-direct injected engines only deliver air to the combustion chamber; fuel delivery is through the sealed injectors (2 on crankcase, 2 on cylinders for your Polaris). So fogging oil will eventually get drawn into the combustion chamber and pushed out the exhaust.

Ignition Systems

Q: I have a 1980 Arctic Cat Trail Cat that I purchased for a mere $100. I have been trying to revive life into it with little success. I have put a new coil and newer CDI on it and still cannot see a spark. What am I missing? The stator does put some light to the taillight when the engine turns over. I have also tried to bypass the key and kill switches. Please help, and keep up the good vintage how-to articles and features.

– Eric Yoder

Elmwood, Illinois

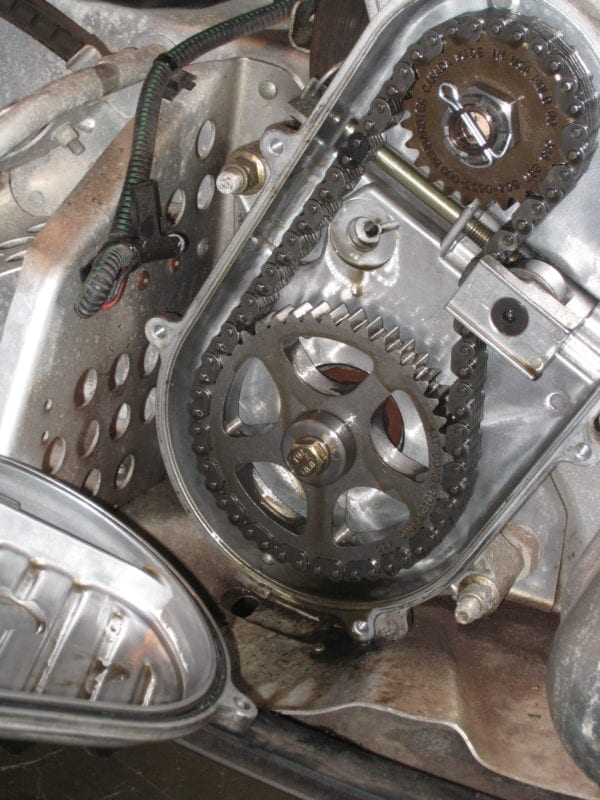

A: Even though the taillight flickers when cranking over the engine, a coil on the stator could be shot. The stator is bolted to the end of the crankshaft and it has a lighting coil, trigger coil and charge coil. The lighting coil on your sled is probably OK because it still provides power to the lights and accessories. The charge coil provides the power to the electrical system, and the trigger coil controls the spark intervals to the ignition system. It’s likely that the stator’s trigger coil has gone bad, but unfortunately Arctic Cat didn’t sell that part separately, so the stator assembly will need to be replaced if the following tests prove it has failed. Measure the resistance between the green wire coming from the stator and chassis ground. It should be 31.2 ohms, +/- 10 percent. If the trigger coil checks out OK, check the charge coil by measuring resistance between the black/white wire and the white/red wire coming from the stator. It should be 148.5 ohms, +/- 10 percent. If any of these resistance measurements are outside of the window of specifications, the stator should be replaced. Unfortunately, the Cat dealer we checked with said the $375 stator assembly is no longer available. Search on the Internet for a used or aftermarket stator; you might even be able to come up with an aftermarket trigger coil. Before going through that hassle, though, check for worn insulation on the wires that lead from the stator; bare wires could be grounding on the chassis. Also, make sure the spark plug caps are healthy as they can also cause poor or weak spark.