Does the “perfect” engine have a long stroke, a big bore, or is it “square?” That answer depends on whether the designer wants that engine to power a tractor or a high-winding sport bike. The world of snowmobiles falls somewhere in between those two extremes – of course we all want great low-end grunt, but also top-end performance. To answer the questions about cylinder design and engine design, Snow Goer Tech Writer T.J. Krob penned this Snowmobile Science column for the January 2016 issue of Snow Goer. To see more articles like this, plus opinionated snowmobile evaluations, aftermarket product tests, snowmobile destination stories and much more, click here to subscribe.

SNOWMOBILE SCIENCE: ENGINE DESIGN

We all learned about shapes in kindergarten. There’s the triangle, circle, square, cylinder and a pile of others along the way. But did you know that the performance of a power sports engine is significantly dependent on its shape?

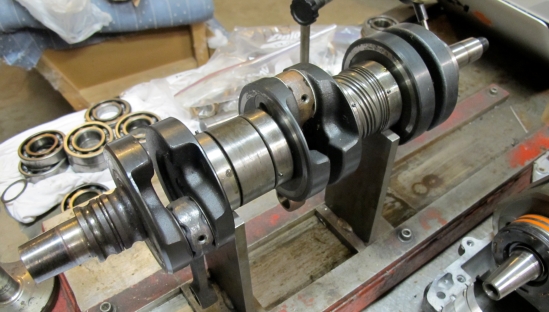

There are several terms that must be defined when speaking of an engine to characterize its overall shape. The bore of an engine is simply defined as the diameter measured across the inside edges of a single cylinder. The stroke of an engine can be measured as the total distance traveled by a piston from its highest point within the bore to its lowest point. Or, taking a step that more precisely defines a piston’s travel dimension: The stroke of the engine is defined as the distance between the centerline of the crankshaft and the centerline of the rod journal arm. Multiply that distance by two – accounting for top-dead center to bottom-dead center – and you have the true crankshaft stroke.

Displacement is the combination of both the bore and stroke of an internal combustion engine. For snowmobiles, this value usually is on the hood as a decal denoting a cubic centimeter measurement of the swept volume by all pistons.

Bore/Stroke Ratios

Dividing the bore by the stroke provides the bore/stroke ratio – an engine with a value of 1 is considered square. The term “square engine” describes a powerplant with a bore and stroke value nearly identical to one another. A square engine will produce max power and max torque at a similar RPM relative to one another, and they operate more efficiently at a low RPM than their over-square counterparts.

An under-square engine will operate at an even lower RPM and be considered a “torquey” engine, thanks to its long stroke. Examining current 600cc two-stroke engines shows that companies each have their own way to get to that volume. For example, the Rotax 600 H.O. in Ski-Doo models is measured to 594.4cc with a 72 mm bore and 73 mm stroke. The 6000 Series Arctic Cat C-TEC2 measures 598.9cc with a 73.8 mm bore and 70 mm stroke. The Polaris Cleanfire measures 599cc with a bore of 77.25 mm and a stroke of 64 mm. While the numbers calculate out to the 600cc benchmark, one engine is nearly right on square, one leans slightly away from square-ness and the third engine is farther away from square.

The Rotax, which at 72/73 equates to 0.9863, is, for all intents and purposes, considered a square engine. The Arctic Cat engine steps to the over-square side with its bore/stroke ratio equaling 1.054. Stepping far into the over-square class is the Polaris power plant with a ratio 1.207. As the math shows, these three snowmobile engines do not represent the category of under-square, but know that low-RPM, high-torque diesels used for pulling typically have a bore/stroke ratio of less than one because they have a much longer stroke than the bore.

Whether the application is for a fast-revving racecar or a tractor needing gobs of low-end torque, theories and opinions vary about engine class bore/stroke ratios.

In general, high revving engines, which produce the most torque at high RPM, are over-square. One-liter sport bike engines fall directly into this category with a stroke about 55 mm and bore about 75 mm, and they wind out to more than 13000 rpm to make peak horsepower. These engines inherently have a shorter cylinder since the stroke is shorter, thus enabling them to fit into height-restricted frames.

Stroke Length, Torque Value & Skirt Design

Peak performance and power curve characteristics are reliant not only on the above dimensions, but also the design of the combustion chamber, piston crown shape – whether domed, flat or dished – rod/stroke ratio, compression and the placement of ports inside the cylinder wall.

When an engine is running at its peak efficiency in terms of air and fuel consumption, peak torque will be present. Though it never would be logical, a powerplant with a relatively long stroke can have a short rod housed inside a tall cylinder. As a result, the displacement of the engine will be low as the swept volume is less; the compression developed inside the cylinder will also be low. This is an inefficient method to build power and space constraints will become apparent as the wrist pin will be too close to the crankshaft at bottom-dead center, and thus run the piston skirt into the crank lobes. But the example shows that many variables are at play to create even a lame duck engine.

Components and parts inside an engine spinning more than 8000 rpm develop some serious forces and generate loads of heat that must be accounted for when designing an engine. A long-stroke engine, or a “stroker,” induces more side piston loading than a short stroke because when the crankshaft rotates to 90 degrees beyond bottom dead center the angle of the rod relative to cylinder centerline is greater, thus pushing the piston against the cylinder wall. At identical engine speeds compared to a short-stroke engine, a longer stroke will also raise the overall velocity of the piston, thus increasing friction that must be mitigated by the cooling system. To maintain durability, these torque monsters are tuned to run at a lower RPM.

Designers of short-stroke engines must keep an eye on the surface area of the piston that can contact the cylinder wall. Not only do they need to make sure ample support is given to the skirt through the entire sweep, but also ensure that the piston travels far enough to open/close the transfer ports so they can suck a new charge into the cylinder. To maintain optimal port timing in a two-cycle engine with a short stroke, engines must have a shorter piston, longer rod or lower wrist pin location, which can leave the piston crown unsupported.

Short-stroke engines must have a piston that extends below the wrist pin a smaller amount – when compared to a long-stroke engine – so the piston skirts don’t contact the crank lobes. To accomplish this, engine designers can either shorten the skirt itself or they can move downward the wrist pin location in the piston to effectively shorten the skirt. By lowering the wrist pin, there will be more piston wall above the wrist pin. This, too, can cause problems if it’s too excessive and the top of the crown slaps the cylinder wall. If the skirt is left long, the cylinder’s “beaver teeth” (if equipped) must extend into the crankcase to support the piston as the piston reaches bottom-dead center. If the beaver teeth are too short, the piston might tilt when it travels up through the bore, a condition known as “beer canning” that will damage the piston skirt.

The variances in the bore vs. stroke ratio in the 600-class two stroke snowmobile engines mentioned earlier are slight enough that they don’t make much difference in the machine’s seat-of-the-pants performance – how they are clutched and geared will likely have a bigger influence that riders can feel when they pinch the throttle. For those who are familiar with the motorcycle world, a better example may be comparing a lugging Harley-Davidson Wide-Glide (with its .886 ratio) to a high-winding Yamaha YZF-R1 sport bike (with its 1.55 ratio). There’s no mistaking the power curves between those two engines.